Ukulele Procedure

These groups can be done in any order but I would do everything in the group together

Group 1 (top and back)

- Glue the book matched top and thin to .8 for spruce or .75 for mahogany

- Draw the outline of the top on the underside of the top. Draw a cut line about ¼” from the outline.

- On the bandsaw, cut to the cut line

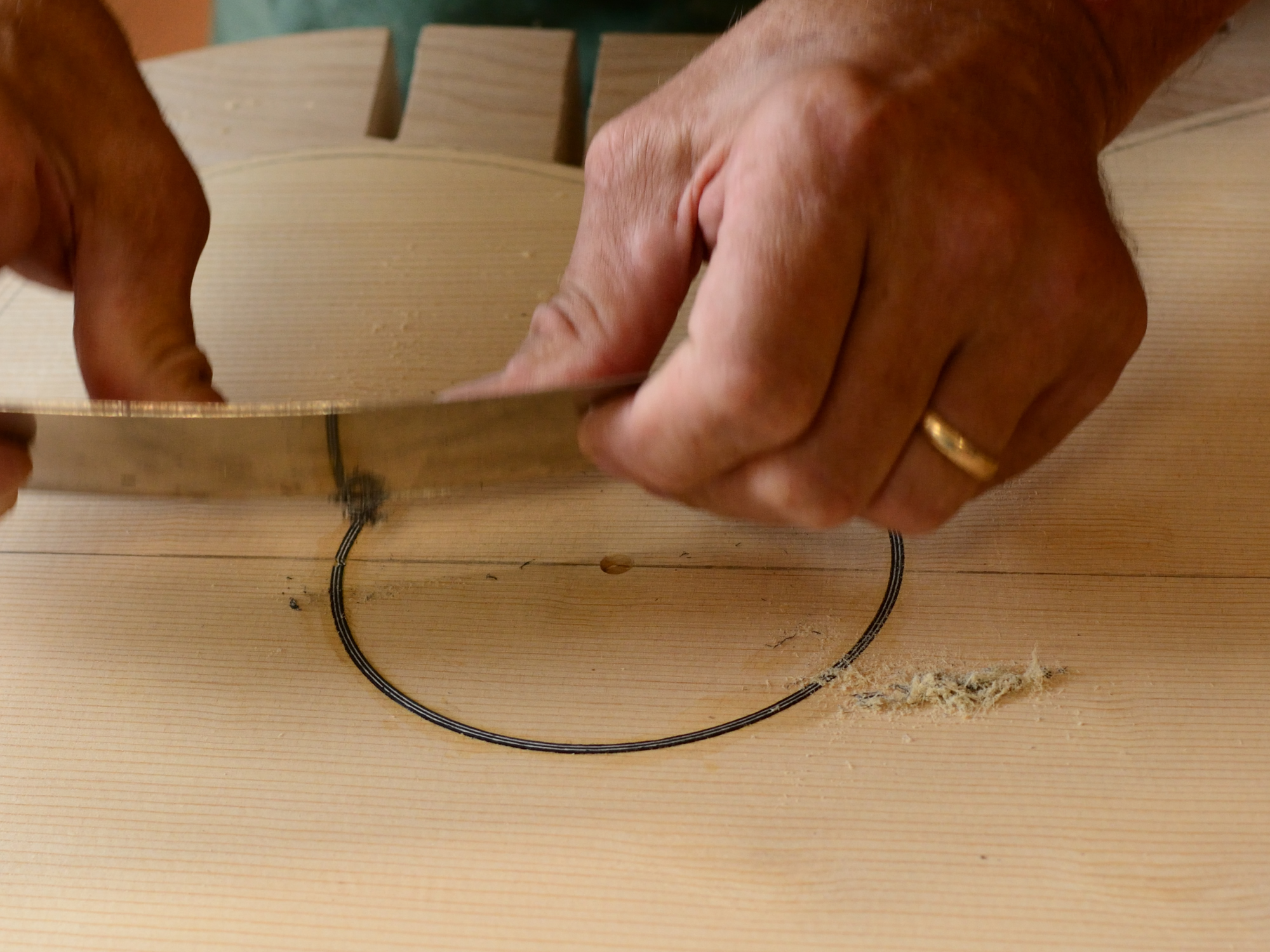

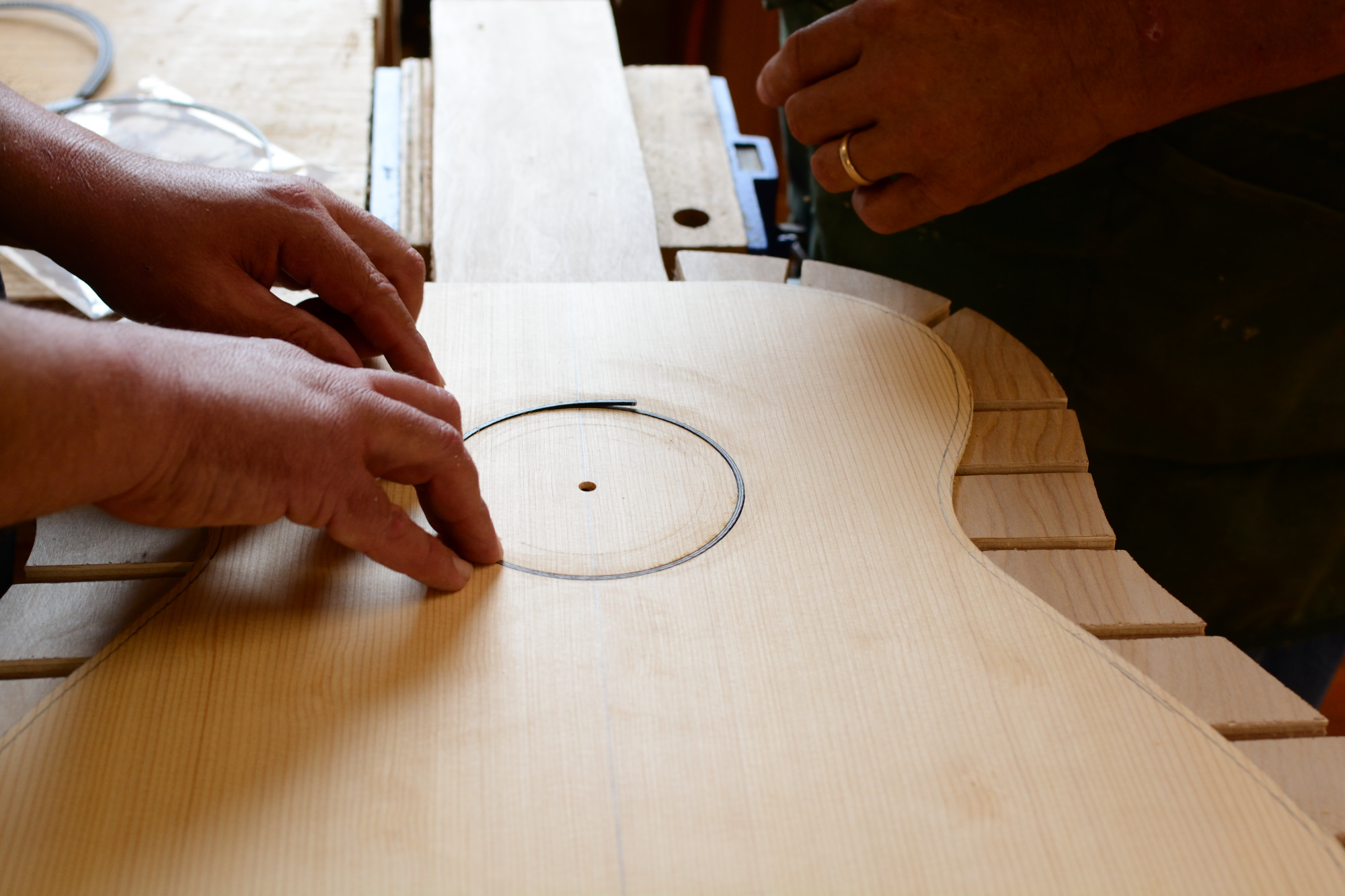

- Drill a ¼” hole in the center of the sound hole to accept the rosette/sound hole cutting jig.

- On the front side cut a rosette channel to match the width and depth of the rosette

- Install a rosette on the top (optional) and cut the sound hole

- Brace the top using the pattern in the plan. Start with the bridge patch so you can notch the long braces over it. Carve the braces as shown in the plan

- Glue the book matched back and thin to between 75 and .8 for mahogany, maybe a little thinner if it sounds like a brick when you tap on it. Draw the outline and also a cut line.

- Cut to the cut line.

- Brace the back using the plan. Carve the braces per the plan

Group 2 (sides)

- Cut the sides to their height (between 2 1/2″ to 2 3/4″ ) and length and thin to .075 to .085 (no thicker or they will be hard to bend). Thinner than .075 and they may be too fragile.

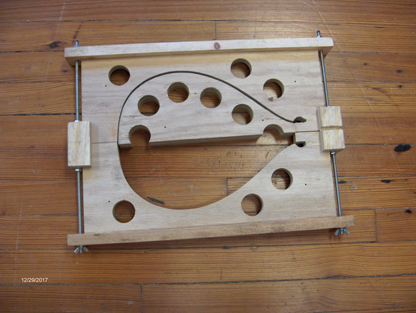

- Bend the sides to their shape using an inside mold. Clamp to the mold and trim at the neck and tail so you can get both sides fit nice to the mold.

- Cut a head block the size of the opening in the mold and cut a mortise on the front side 3/4″ wide and 1/4″ deep

- Cut a tail block to fit the size of the opening in the mold and the height of the sides

- Glue the sides to the head block and tail block paying attention to keeping everything flat to one side and tight to the mold.

- Apply kerfing to the top. (see group 4 for making kerfing) Keep the top of the kerfing just slightly above the sides enough that your fingernail catches it. I find it best to push the side assembly up the mould enough to get clamps on the kerfing and keep the sides clamped in the mold until the top kerfing is installed. This helps keep the shape of the sides.

- When the kerfing is dry sand the side assembly flat using a sanding board.

- Install kerfing on the back and sand flat when dry.

Group 3 (neck)

- Glue a neck blank (or use a solid block of wood). There are two templates. One is the side profile, one is the top. Use the templates for the size and shape of the neck. Don’t cut the profiles at this time just get the block ready

- Cut the tenon on one end to fit the head block.

- Using the cheeks of the tenon as a reference, align the 12th fret mark on the side profile template even with the cheeks and trace (with the fretboard side of the template and the neck blank on a flat surface) and bandsaw the side profile (leave the line)

- Measure from the cheeks of the tenon (12th fret) toward the peghead 7 3/8″ and mark a line across the fingerboard side of the neck. Next measure toward the peghead another 3/16″ and mark a line. These two lines are where the nut will sit.

- CAREFULLY plane or sand on a belt sander the face of the peghead till you have a crisp interfacing plane between the fretboard plane and the peghead plane at the top of the nut (the last line you drew).

- Now clean up the back side of the peghead till it is 1/2″ thick.

Group 4 (make kerfing)

- Cut strips of mahogany 1/4″ thick and 5/8″ tall and at least 16″ long although longer is better

- Use the jig to cut the angle on one side of the strip (get some help setting up the jig)

- Use another jig to cut the slots or kerfs. You will need 4 pieces at least 16″ long. kerfing doesn’t have to be a continuous piece.

Assembly 1 (gluing the top to sides)

- Place the side assembly over the top and mark on the braces the outside of the sides. Mark on the kerfing, the sides of the braces.

- For the braces that go under the kerfing cut away the kerfing over the braces. Cut the ends of the braces to the inside of the sides. You will add individual kerfing pieces over the top of the braces once the top is glued. This keeps the braces from popping loose sometime down the road.

- For the braces that don’t go under kerfing, mark them at the kerfing and trim.

- Check all the way around the sides to make sure the top fits tight to the sides with no gaps. Make adjustments as necessary. Make sure the center line of the top aligns with the center line of the headblock and the tail block.

- Apply glue to the kerfing and clamp the top to the sides using spool clamps (lots of them).

- After the top is glued, glue individual kerf blocks over the braces where you trimmed out the kerfing.

- Trim the excess top using a flush trim router bit or by hand.

Assembly 2 (fitting neck to body)

- Cut the tenon slot out of the top

- Place the neck and top face down on a flat surface with the neck tenon in the headblock mortise.

- Make a mark on the headblock center line 1” from the bottom of the ukulele. Drill a ¼” hole through the head block and into the neck the length of a threaded insert.

- Enlarge the hole in the neck to accept the threaded insert and install it.

- Bolt the neck to the body and check alignment. The neck should be flat to the top and aligned with the center line of the ukulele. If the neck is not straight on the centerline carefully shave one side to bring into alignment. This is best done by using a chisel and trimming first close to the tenon and then easing out to the edge of the neck.

Group 5 (Fretboard and neck after assembly 2)

- Make a Fretboard blank 3/16” thick 10” long and 2” wide

- Using the fret saw blade and the template, cut fret slots on the little table saw.

- Trim the nut end of the Fretboard to the nut slot that was cut.

- Install position markers at frets 3, 5, 7, 10, 12 (install 2 here),and 15

- Using the template, outline the Fretboard design. Cut on the bandsaw but leave the line. Plane or sand to the line.

- Place a 3/16” nut in its place on the neck and align the Fretboard taking care that it is centered.

- Glue the Fretboard to the neck using strips of inner tube to securely clamp it.

- Once dry install frets. Dress the edges of the frets with a flat file then file the ends about 30 degrees and file away the burrs.

Group 6 (carving the neck)

- Cut the peghead to the desired shape keeping in mind where you will install tuners

- Use various shaping tools to shape your neck to the desired shape. I’ve found a spokeshave works pretty well in the areas it can reach. Then I use microplanes to get a rough shape. I use a course file to get a final shape then 80 grit sandpaper. Once I’m happy with the feel of the neck I sand with 150 then 220 grit.

Assembly 3 (attaching the back)

- Place the back over the body and mark where the braces need to be trimmed. Mark on the sides of the ukulele where kerfing will need to be trimmed.

- Cut a pocket in the kerfing to accept the braces

- Test fit the back and if everything looks good (proper alignment and no gaps) glue the back to the body using spool clamps

- Trim the excess back using a flush trim router bit or by hand

Assembly 4 (binding the body)

- Select your binding or make some approximately 1/16” thick and ¼” tall.

- Using the binding cutter jig, cut the binding channel.

- IMPORTAINT – test fit the binding along the entire binding channel and cut more where needed.

- Trim the binding at the tail block for a tight fit. The top binding can extend into the neck mortise and be cut after glued. The back binding needs to be a tight fit at the tail and head.

- Glue the top binding in the channel starting at the tail block. Use blue tape to hold in place until you get both pieces in place. Wrap the entire ukulele with inner tubes to hold the binding in place.

- Allow a couple hours to dry before removing the inner tubes. They act like a bottle and the glue takes longer to dry.

- When the inner tubes come off, clean the binding by scraping flush to the top and sides. Be careful to not scrape too thin. This is where checking your binding channel really pays off.

- Repeat for the back

Group 7 (making the bridge, nut, and saddle)

- Make the bridge slightly over ¼” thick x 1” wide x 3 1/8” long Start with a longer stick as it is easier to handle.

- Set the depth of cut to 5/32”

- Cut a 1/8” slot the entire length of the stick 1/8” from the edge

- Cut another 1/8” slot the entire length of the stick 5/8” from the same edge

- Now tilt the saw 30 degrees and set the width from the tip of the saw blade to the fence to 5/8”

- With the saw set back to 90 degrees cut a blank 3 1/8” long

- In the cross cut sled set the depth of cut to 5/32”. Nibble off the ends leaving a 2 1/16” center. Smooth with a flat file and sand to 220 grit.

- Drill 4 1/16” holes for strings through the wide section of the bridge. Space the holes 9/16” apart starting 3/16” from the edge. When drilling, tilt the bridge forward 1/16” at the top edge. I use a piece of binding to tilt it. This has the holes at an angle making it easier to thread the strings.

Assembly 5 Install the bridge

- You can install the bridge before finishing or tape off the bridge location and finish or finish and scrape away the finish under the bridge. Here’s how you set the bridge location.

- There is a template that is the string length of 14 ¾”. You place one end against the nut and place the middle of the saddle slot at the other end. Carefully tape off the bridge location either under it if you are finishing without a bridge installed or around it if you plan to glue the bridge prior to finishing or after you have scraped away the finish.

- Glue the bridge. Clamp with light pressure using 4 cam clamps

Finishing

- Sand to 220 grit then wet sand with 400grit to see if there is any glue you missed.

- Final sand to at least 320, more if you like.

- Finish with your favorite finish. I find mahogany needs to have the pores filled to get a nice finish.

Assembly 6 (putting it together)

- Cut a saddle to fit the slot extending above the bridge by 3/32” to 1/8”

- Cut a nut 3/16” thick and place in its location. With a half pencil laying on the frets, scribe a line on the face of the nut. Cut 1/16” above the line.

- Cut and file for strings down to just touching the line, no more.

- String are spaced 3/8” on center and centered on the nut

- String it, tune it, play it.